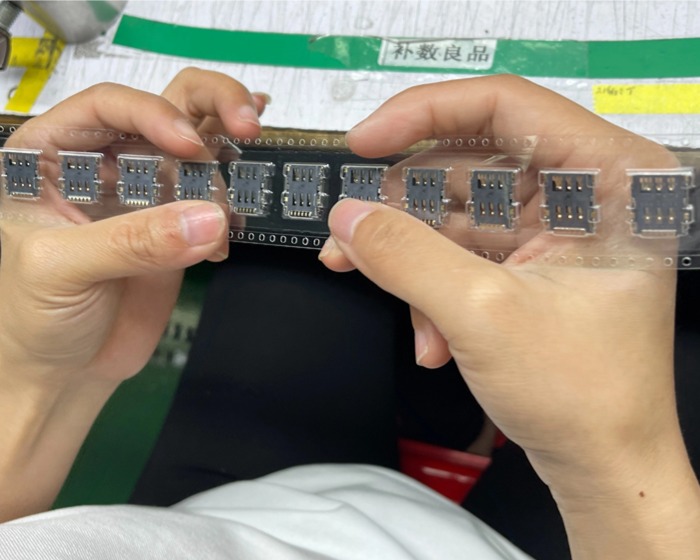

Trust & Quality

Semi-Annual Reliability Testing of Card Connectors

Reliability testing is an important means of comprehensively examining the performance and stability of card connectors in a variety of extreme environments. We understand that only through rigorous testing can our products demonstrate outstanding performance and stability in real-world applications. Therefore, every six months, Moarconn puts each type of card connector under a variety of extreme environments, such as high temperature, low temperature, high humidity, low humidity, vibration, salt spray, etc., in order to simulate the various conditions that the connector may encounter in actual use.During the testing process, we will comprehensively examine the electrical performance, mechanical performance, environmental adaptability, service life and other aspects of the card connectors. Through these tests, we are able to identify and solve the problems that may exist in the design and production process of the card connectors in a timely manner, to ensure that each connector can meet our strict quality standards.Reliability testing is an important means of comprehensively examining the performance and stability of card connectors in a variety of extreme environments. We understand that only through rigorous testing can our products demonstrate outstanding performance and stability in real-world applications. Therefore, every six months, Moarconn puts each type of card connector under a variety of extreme environments, such as high temperature, low temperature, high humidity, low humidity, vibration, salt spray, etc., in order to simulate the various conditions that the connector may encounter in actual use.