How Push-Push Card Connectors Work — Step-by-Step Explanation, Pros & Cons

Introduction

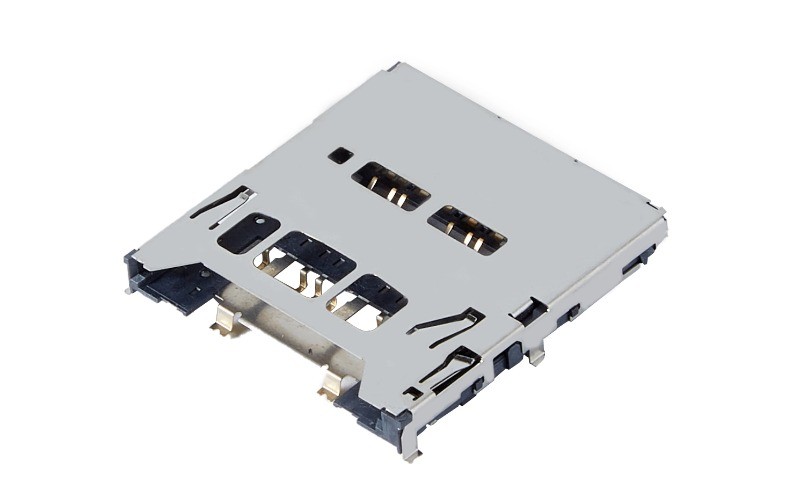

As electronic devices continue to shrink in size, the Push-Push card connector has become one of the most widely used mechanisms in SD, Micro SD, and SIM card interfaces. Combining convenient operation with mechanical reliability, this guide—based on Moarconn’s manufacturing expertise—explains how Push-Push connectors work, their advantages, limitations, and industrial applications.

1. How Push-Push Mechanism Works (Step-by-Step)

The Push-Push connector uses a two-stage mechanical design that allows users to insert and eject the card with simple press actions.

Step-by-step process:

Insertion:

The user pushes the card inward; the spring inside compresses as the sliding rail engages.

Locking:

When fully inserted, the latch locks the card in place to ensure stable electrical contact.

Ejection:

A second press releases the latch, and the spring pushes the card out automatically.

2. Advantages of Push-Push Mechanism

User-friendly: Tool-free insertion and ejection enhance usability.

Durability: Moarconn’s phosphor bronze contacts ensure 5000+ mating cycles.

Compact Design: Perfect for small form-factor devices such as wearables and automotive systems.

Secure Locking: Maintains stable signal contact and minimizes data loss.

3. Potential Drawbacks

Complex Design: Requires precise tooling and high-accuracy molding.

Limited Sealing: Additional sealing is needed for outdoor or industrial applications.

Spring Fatigue: Poor-quality materials may lead to ejection issues over time.

4. Common Applications

Push-Push card connectors are widely used in:

Smartphones, tablets, GPS systems

Security cameras and industrial controllers

Consumer electronics such as digital cameras and wearables

5. Why Choose Moarconn

As a professional card connector manufacturer, Moarconn (www.moarconn.com) integrates tooling, injection molding, stamping, plating, and automated assembly under one roof.

Product Range: SIM, Nano SIM, SD, and Micro SD connectors

Quality System: Certified under ISO 9001

Customization: Supports OEM design for structure and electrical performance

6. Conclusion

The Push-Push connector’s reliability and ease of use make it an essential component in modern electronics. Partnering with Moarconn, a precision-driven factory specializing in connector innovation, ensures your products achieve stability, performance, and long-term quality.