How to Choose a Reliable Card Socket Connector Manufacturer from a Customer's Perspective ?

In the global electronics supply chain, the reliability of card socket connectors directly impacts the lifespan and safety of end products. As a procurement decision-maker, are you concerned about supplier quality fluctuations causing batch returns? Based on in-depth research , this article reveals the essential quality control practices that top-tier card socket connector manufacturers must master to help you identify the best suppliers.

1. Certifications & Quality Control

- International Certifications: Prioritize manufacturers with ISO quality management systems (e.g., ISO 9001, ISO 14001) and industry-specific certifications (e.g., ROHS, EMV, PCI). For example, MOARCONN. holds ISO 9001 and ISO 14001 certifications, complies with ROHS standards, and has passed NDS and EMV certifications, ensuring reliable quality.

- Quality Control Process: Check whether the manufacturer implements strict control throughout the entire process, from design and mold processing to testing. Companies like Dehaiwei and Moarconn Electronics emphasize full-process quality control to ensure product stability.

2. Production Scale & Technical Capabilities

- Facilities & Equipment: Large-scale factories and automated equipment ensure production capacity and technical reliability.

- R&D Capabilities: Choose manufacturers with professional technical teams.

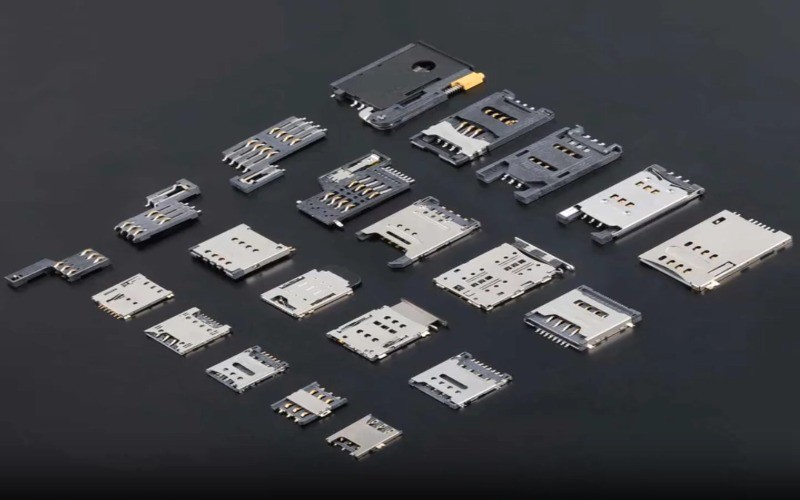

3. Product Performance & Materials

- Durability & Specifications: Focus on key metrics such as insertion cycles and temperature resistance. For example, Moarconn Electronics' SD card sockets have a lifespan of 10,000 cycles, and Tesca Industrial Electronics' SIM card sockets support 5,000 cycles, using high-temperature-resistant materials like LCP and phosphor bronze.

- Application Suitability: Select products tailored to specific industries (e.g., automotive, medical). Moarconn’s products are used in banking equipment and automotive electronics, while Tesca’s products cover automotive and medical applications.

4. Supply Capacity & Responsiveness

- Lead Time: Confirm minimum order quantities (MOQ) and delivery times. Moarconn Electronics supports orders as low as 1,000 units with a 3-day turnaround, suitable for many kinds-of-medium batches.

- Supply Chain Layout: Manufacturers with multiple locations improve logistics efficiency. Moarconn has facilities in Dongguan, facilitating easier coordination for clients.

5. Industry Reputation & Customer Cases

- Corporate Partnerships: Manufacturers collaborating with well-known companies are more credible. MOARCONN has long-term partnerships with global enterprises and is recognized in the electronics industry.

- Customer Reviews : Check third-party platforms or industry feedback. For example, Moarconn Electronics is praised for its professional product descriptions and case studies.

6. After-Sales Service & Technical Support

- Customization Services: Choose manufacturers offering design support. Fengshuo Electronics provides cost-effective solutions and design services based on customer needs.

- After-Sales Response: Ensure the manufacturer has a dedicated support team. Moarconn emphasizes a "customer-first" approach, and offers technical parameter consultations.

Final Recommendations

Customers should evaluate manufacturers based on their specific needs (e.g., order volume, application, certification requirements) and prioritize sample testing or on-site inspections. Additionally, balance cost and quality—avoid choosing solely based on low prices at the expense of long-term reliability. By referencing the above criteria and reviewing manufacturer websites or third-party platforms (e.g., Made-in-China, industry exhibitions), customers can efficiently identify high-quality suppliers.