How to Choose a TF Card Connector for Your Product

Introduction: Why TF Card Connector Selection Matters

TF card connectors (also known as Micro SD card connectors) play a critical role in modern electronic devices by providing removable storage, data transfer, and system expandability.

However, selecting the wrong TF card connector can lead to signal instability, mechanical failure, poor user experience, or even product recalls.

This technical guide is written for hardware engineers, product designers, and sourcing professionals who want to choose the right TF card connector based on mechanical design, electrical performance, application environment, and long-term reliability.

What Is a TF Card Connector?

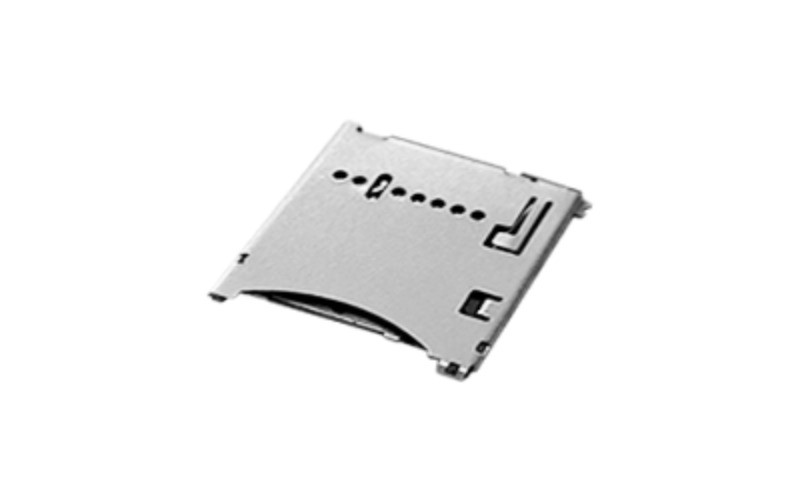

A TF card connector is a compact electromechanical interface that connects a TF (Micro SD) memory card to a printed circuit board (PCB). It ensures stable electrical contact, secure card retention, and repeated insertion without performance degradation.

TF card connectors are widely used in consumer electronics, industrial equipment, IoT devices, automotive systems, and embedded applications.

Key Factors When Choosing a TF Card Connector

1. Connector Mechanism: Push-Push vs Push-Pull vs Hinged

One of the first decisions engineers must make is the mechanical insertion mechanism.

• Push-Push (Self-Eject): One press to insert, one press to eject, excellent user experience

• Push-Pull: Manual pull-out, simple structure, higher stability

• Hinged / Flip Type: Metal cover protection, strong retention force

2. Electrical Performance & Signal Integrity

TF card connectors must maintain reliable contact for high-speed data transmission.

Key parameters include contact resistance, voltage/current rating, and high-speed signal stability.

MOARCONN TF card connectors use precision copper alloy contacts with gold plating to ensure consistent electrical performance over long service life.

3. Mechanical Durability & Mating Cycles

Mechanical durability is critical for products designed for long service life.

Engineers should review insertion cycles, retention force, and spring fatigue resistance.

4. PCB Mounting & Design Constraints

Most TF card connectors are surface-mount (SMT).

Designers must consider connector height, pad layout, card-detect switch availability, and assembly compatibility.

5. Application Environment & Reliability Requirements

Environmental conditions such as vibration, temperature, dust, and usage frequency strongly influence connector choice.

MOARCONN provides TF card connectors suitable for consumer, industrial, and automotive applications with strict quality inspection and long-term supply capability.

Why Engineers Choose MOARCONN TF Card Connectors

MOARCONN combines precision manufacturing, engineering expertise, and stable supply to support reliable TF card connector solutions.

Conclusion

Choosing the right TF card connector directly impacts product reliability, user experience, and lifecycle.

Working with an experienced manufacturer like MOARCONN helps reduce design risk and improve product success.