Nano SIM Connector Selection Guide Key Specs & Design Tips for Engineers

Introduction: Why Nano SIM Connector Selection Matters

As cellular connectivity becomes a core requirement in IoT devices, wearables, industrial terminals, and smart electronics, the demand for reliable Nano SIM connectors continues to grow.

Although often considered a minor component, a Nano SIM connector plays a critical role in signal stability, device durability, and long-term product reliability. Improper selection can lead to intermittent connections, SIM card damage, or costly redesigns during mass production.

This engineer-focused guide explains how to select the right Nano SIM connectors, covering key specifications, mechanical design considerations, and real-world application insights—based on industry-leading selection guides and Moarconn’s extensive manufacturing experience.

What Is a Nano SIM Connector?

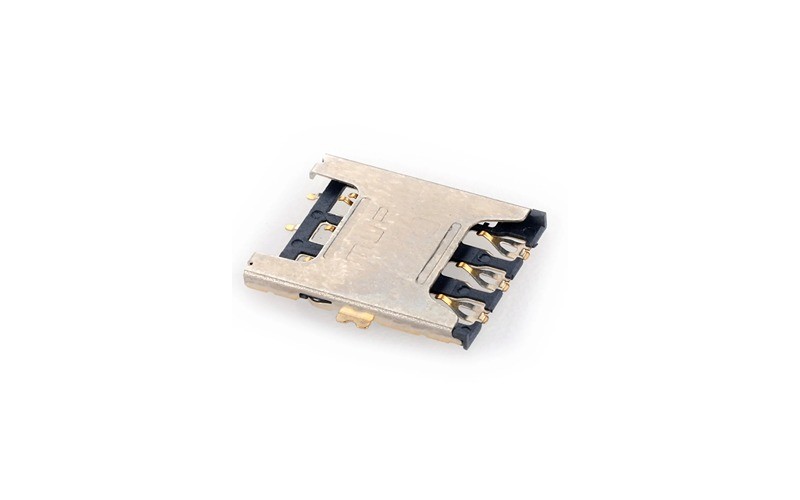

A Nano SIM connector is a compact electromechanical interface designed to connect a 4FF Nano SIM card (12.3 × 8.8 mm) to a device’s PCB. It ensures stable electrical contact between the SIM card and the modem, enabling authentication and cellular communication.

Compared with Micro or Mini SIM connectors, Nano SIM connectors offer a smaller footprint, lower profile height, and better compatibility with modern LTE, 5G, NB-IoT, and Cat-M modules.

Moarconn provides a comprehensive portfolio of Nano SIM connectors supporting multiple insertion mechanisms and mounting styles.

Common Nano SIM Connector Types

Push-Push (Self-Eject) Nano SIM Connectors

One-handed insertion and ejection

Integrated spring mechanism

User-friendly for consumer electronics

Requires precise mechanical design

Push-Pull Nano SIM Connectors

Simple structure with high reliability

Lower cost and lower profile options

Common in industrial and embedded systems

Hinged & Tray-Style Connectors

Enhanced resistance to vibration

Suitable for sealed or rugged enclosures

Preferred in automotive and industrial equipment

Key Specifications Engineers Must Evaluate

1. Mechanical Durability & Insertion Cycles

Typical Nano SIM connectors are rated for:

5,000 insertion cycles (consumer devices)

10,000+ cycles (industrial-grade designs)

Moarconn industrial Nano SIM connectors use high-elastic copper alloy contacts with optimized gold plating to maintain stable contact force over long-term use.

2. Contact Plating & Electrical Reliability

Electrical reliability depends on gold plating thickness, contact force stability, and corrosion resistance. Enhanced plating options are recommended for harsh or long-life applications.

3. Connector Height & PCB Footprint

Low-profile design is critical for wearables, handheld devices, and compact IoT modules. Engineers must balance mechanical strength with height reduction.

4. Card Detection Switch (CD)

Card detection switches help systems identify SIM presence and improve firmware reliability. Moarconn offers Nano SIM connectors with optional integrated CD switches.

5. Environmental & Application Requirements

For IoT and industrial use, temperature range, vibration resistance, and humidity tolerance must be considered.

Why Engineers Choose Moarconn Nano SIM Connectors

Moarconn delivers:

A complete Nano SIM connector portfolio

Proven reliability in IoT and industrial markets

Customization support for height, plating, and detection

Stable long-term supply and engineering support

https://www.moarconn.com

Conclusion

Choosing the right Nano SIM connector directly impacts device reliability, user experience, and product lifecycle. Early, informed selection helps engineers avoid costly redesigns and ensure long-term performance.