Optimizing High-Speed Data Integrity in Micro SD Connector Designs

Why Data Integrity Matters in High-Speed Designs

In the era of high-speed data communication and miniaturized electronics, micro SD connectors must go beyond physical connectivity — they must maintain signal integrity across high-frequency channels. As micro SD cards reach UHS-I and beyond, maintaining clean, interference-free signals is crucial for data reliability, system stability, and product longevity.

Understanding Signal Integrity Challenges

When dealing with high-speed interfaces like micro SD 3.0 or UHS-I standards (up to 104 MB/s), poor connector design or PCB layout can lead to issues such as:

Insertion Loss (IL) – power loss due to impedance mismatch

Crosstalk (XT) – signal leakage between adjacent pins

Return Loss (RL) – reflection from discontinuities

Electromagnetic Interference (EMI) – especially in compact consumer electronics

According to Fischer Connectors, even slight discontinuities in connector geometry can create reflection points that disrupt data communication in SD interfaces.

Design Techniques for High-Speed Micro SD Connectors

Based on industry best practices from Greenconn and STMicroelectronics, here are key strategies for optimizing connector signal integrity:

1. Controlled Impedance Design

Ensure impedance matching (typically 50 ohms) throughout the micro SD signal path. This reduces return loss and reflections.

2. Short Signal Paths & Minimal Vias

Keep trace lengths short and avoid excessive via transitions to preserve signal shape.

3. Ground Shielding

Use surrounding ground planes and shielded connector designs to minimize EMI and improve crosstalk rejection.

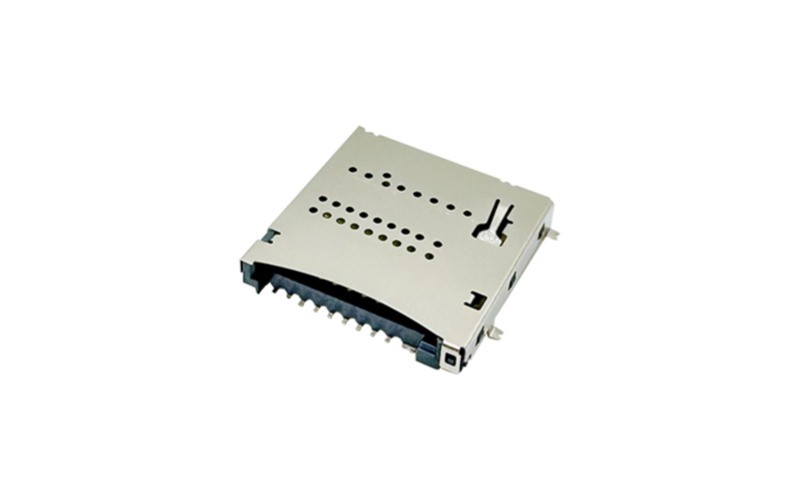

4. Low Profile, High Precision Connectors

Select micro SD connectors with tight tolerances and low-profile structures that reduce discontinuities.

Moarconn's High-Speed Micro SD Connector Solutions

At Moarconn, we understand the challenges of high-frequency signal integrity. That’s why our Micro SD connector series is engineered with:

Controlled impedance pin layouts

Durable contact materials with gold plating

Optimized shell shielding to reduce EMI

Customizable insertion force and cycle life (≥10,000 times)

Compact footprint for space-constrained applications

We have served high-performance sectors including industrial control, automotive electronics, and IoT devices, helping engineers improve data accuracy in high-speed systems.

Real-World Application Example

When developing a compact GPS module with SDIO interface, one of our clients faced data dropouts due to signal reflection. By switching to Moarconn’s shielded micro SD connector with enhanced pin impedance control, they improved throughput by 22% and passed SD3.0 EMI compliance tests.

Conclusion

Optimizing high-speed data integrity in micro SD connector designs is not optional — it’s essential. From connector geometry to PCB layout to EMI mitigation, every detail counts. At Moarconn, we’re not just a component supplier — we’re your partner in delivering performance-critical connectivity for the digital future.

Visit www.moarconn.com to explore our full range of high-speed micro SD connector solutions or request custom support from our technical team.