The Ultimate Guide to Custom SD Card Connector Manufacturing: Design, Materials, and Process

In today's ever-shrinking electronic landscape, every component matters. The humble SD card connector, the crucial gateway to removable storage, is no exception. While standard off-the-shelf connectors suffice for many applications, the demand for custom-designed SD card connectors is surging. Customization allows engineers to optimize for space, durability, and specific environmental conditions, ensuring peak performance and reliability. This guide explores the critical aspects of customizing and manufacturing SD card connectors, from initial design considerations to final quality assurance.

What Exactly is an SD Card Connector?

An SD card connector, also known as an SD card socket or slot, is an electro-mechanical component that provides a physical and electrical interface between an SD (Secure Digital) memory card and a device's printed circuit board (PCB). Its primary function is to enable reliable data transmission while securely holding the card in place. A typical connector consists of a plastic housing, multiple metal contact pins, and a shell. These components work in unison to facilitate features like hot-swapping and protect against incorrect card insertion.

Why Customization is Crucial in Modern Electronics

Off-the-shelf connectors are designed for general-purpose use, but modern devices often have unique constraints. For applications in industrial automation, automotive systems, medical devices, and compact IoT gadgets, customization is not just a luxury—it's a necessity. Custom solutions can address specific needs for profile height, footprint, pin configuration, and robustness that standard parts cannot meet. A custom connector can be the key to a successful product launch, ensuring the final device is both functional and resilient.

Key Factors for SD Card Connector Selection and Customization

When designing a custom connector, several factors must be considered to ensure it meets the application's unique demands. Partnering with an experienced manufacturer allows you to fine-tune these elements for optimal results.

- Form Factor: The choice between standard SD, microSD, or even combo SIM/SD connectors is the first step. For highly compact devices, a low-profile microSD connector is often preferred.

- Ejection Mechanism: Different mechanisms suit different use cases. The most common are:

- Push-Push: The user pushes the card to insert it and pushes it again to eject. Ideal for consumer electronics where ease of use is paramount.

- Push-Pull: The user pushes the card to insert and manually pulls it to remove. This simple design is robust and cost-effective.

- Hinged/Tray: A hinged lid secures the card, offering excellent protection against vibration and shock, making it suitable for industrial and automotive applications.

- Mounting Style: Connectors can be mounted on the PCB in several ways, including Surface Mount Technology (SMT), Through-Hole, or Reverse Mount, depending on the board layout and manufacturing process.

- Card Detection Switch: A built-in switch that detects the presence of a card is essential for enabling hot-swap functionality and providing feedback to the system.

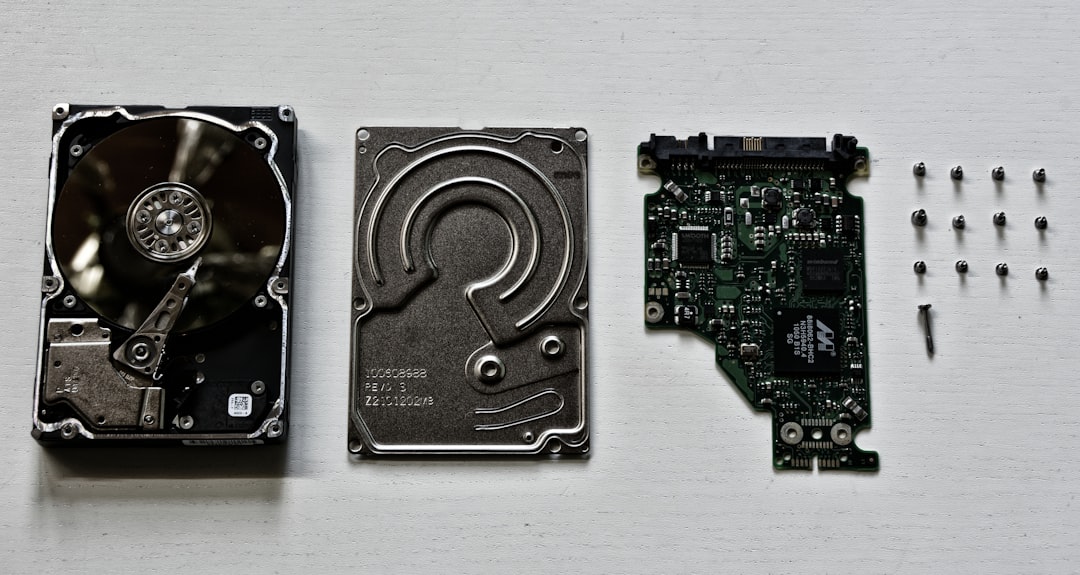

The Manufacturing Process: From Raw Material to Finished Connector

The creation of an SD card connector is a multi-stage process that requires immense precision. This process can generally be divided into four key stages:

1. Stamping

The process begins with the high-speed stamping of metal contacts (pins). A thin strip of metal, typically a copper alloy, is fed into a stamping press, where a series of dies cut and form the intricate shapes of the contact pins. Precision here is critical to ensure reliable electrical connections later on.

2. Electroplating

After stamping, the contacts are electroplated. A thin layer of a precious metal like gold or tin is applied to the contact surfaces. Plating serves two purposes: it improves electrical conductivity and provides crucial protection against corrosion and wear, significantly extending the connector's lifespan.

3. Injection Molding

Simultaneously, the connector's housing is created via injection molding. Pellets of high-temperature thermoplastic resin, such as Liquid Crystal Polymer (LCP) or PA9T, are melted and injected into a custom mold. This forms the insulating body that will hold the metal contacts and provide the connector's physical structure. LCP is often chosen for its ability to withstand the high temperatures of the SMT reflow soldering process.

4. Assembly

The final stage is assembly, where the stamped contacts are precisely inserted into the molded plastic housing. This is typically an automated process to ensure consistency and accuracy. The metal shell, if required, is also attached at this stage. Following assembly, the connectors undergo rigorous testing.

Material Selection: The Foundation of Durability and Performance

The choice of materials directly impacts the connector's mechanical durability, electrical performance, and environmental resistance. Two main components dictate material choice:

- Insulator (Housing): High-temperature thermoplastics like LCP are favored for their dimensional stability and resistance to heat during soldering. The material must also comply with safety standards like UL94V-0 for flammability.

- Contacts (Pins): Copper alloys such as phosphor bronze or beryllium copper are commonly used due to their excellent electrical conductivity and mechanical strength. The choice of alloy depends on the required durability and mating cycles. Gold plating is the industry standard for contact points, offering low contact resistance and high corrosion resistance.

| Component | Common Materials | Key Properties |

|---|---|---|

| Housing | LCP, PA9T, PPS | High-temperature resistance, dimensional stability |

| Contacts | Phosphor Bronze, Brass | High conductivity, good elasticity |

| Plating | Gold, Tin | Low contact resistance, corrosion resistance |

PCB Layout and Design Considerations

A well-designed connector is only as good as its implementation on the PCB. Proper layout is critical for signal integrity, especially for high-speed standards like UHS-II and SD Express.

- Placement: Position the connector near the edge of the PCB for easy user access and to simplify trace routing. Keep it away from high-frequency components to minimize electromagnetic interference (EMI).

- Trace Routing: Keep data and clock traces short, of equal length, and properly shielded. A continuous ground plane under the traces helps ensure signal integrity.

- Impedance Control: For high-speed signals, traces should be routed to maintain a characteristic impedance, typically 50Ω.

- ESD Protection: Place ESD protection diodes close to the connector's signal pins to protect the system from electrostatic discharge.

Durability and Lifecycle Expectations

For any removable media interface, durability is a primary concern. SD card connectors are rated for a specific number of insertion and removal cycles. While a standard consumer-grade connector might be rated for 1,500-5,000 cycles, industrial-grade connectors are engineered to withstand 10,000 cycles or more. Reliability is also tested against environmental factors, with industrial connectors often rated for an operating temperature range of -40°C to +85°C.

Quality Control and Testing Protocols

Rigorous quality control is essential throughout the manufacturing process. Automated optical inspection (AOI) systems are used to detect defects during stamping and molding. After assembly, each connector undergoes functional testing, which may include:

- Contact Resistance Test: Ensures a low-resistance electrical path.

- Withstanding Voltage Test: Checks for insulation integrity between contacts.

- Insertion/Extraction Force Test: Measures the force required to mate and un-mate the card, ensuring it meets specifications.

- Vibration and Shock Tests: Simulates real-world conditions to verify mechanical stability.

Common Applications and Use Cases

Custom SD card connectors are essential in a wide variety of fields:

- Consumer Electronics: Digital cameras, smartphones, drones, and tablets rely on compact and reliable microSD connectors.

- Industrial Automation: PLCs, IoT modules, and data loggers use robust connectors that can withstand harsh factory environments.

- Automotive Systems: Infotainment centers, dashcams, and navigation systems require connectors that are resistant to extreme temperatures and vibration.

- Medical Devices: Portable patient monitors and data logging equipment need highly reliable connectors to ensure data integrity.

How to Partner with the Right Manufacturer

Choosing the right manufacturing partner is as important as the design itself. Look for a manufacturer with deep expertise in precision connectors, from mold design to final assembly. An ideal partner should offer rapid prototyping, support for low minimum order quantities (MOQ), and a proven track record of quality control and adherence to international standards like RoHS and REACH. Collaboration with an experienced manufacturer can shorten development cycles and mitigate costly design errors.

In conclusion, the customization and manufacturing of SD card connectors is a sophisticated process that balances mechanical design, material science, and electrical engineering. By carefully considering all aspects—from the ejection mechanism and material selection to PCB layout and quality testing—engineers can develop robust, reliable, and perfectly tailored solutions for any electronic device.