Industrial & Automotive SD Memory Connectors: Selection Criteria & Reliable Design Guide

1.Introduction: Why SD Memory Connectors Matter in Industrial & Automotive Applications

SD Memory connectors play a critical role in industrial automation, automotive electronics, and embedded systems where data reliability is non-negotiable. Unlike consumer electronics, industrial and automotive environments expose connectors to extreme temperatures, vibration, mechanical shock, EMI, and long service cycles.

Selecting the wrong SD connector may lead to data corruption, intermittent failures, or even system shutdowns — making connector selection a key engineering decision, not a commodity choice.

2. Key Selection Criteria for Industrial & Automotive SD Memory Connectors

2.1 Mechanical & Environmental Reliability

• Wide Operating Temperature Range: Industrial-grade SD connectors typically support -40°C to +85°C or higher, suitable for outdoor and in-vehicle electronics.

• High Durability: A minimum of 5,000–10,000 insertion cycles is recommended for long-life systems.

• Vibration & Shock Resistance: Reinforced structures and stable contact designs prevent signal interruption in high-vibration environments.

CN

2.2 Electrical Performance & Signal Integrity

• Gold-Plated Contacts: Ensure low contact resistance and corrosion resistance over time.

• SD Standard Compliance: Support for SD, SDHC, SDXC, and UHS-I/UHS-II ensures compatibility and future scalability.

• Stable Contact Design: Dual-contact or reinforced pin structures improve reliability under vibration.

CN

2.3 EMI / ESD & Safety Compliance

• EMI Shielding: Metal shells reduce electromagnetic interference in industrial power environments.

• ESD Protection: Critical for automotive and industrial electronics exposed to human interaction.

• Material Compliance: UL-rated, RoHS & REACH compliant materials ensure regulatory approval.

3. Mounting Types & PCB Integration Best Practices

Common mounting options include SMT top-mount, bottom-mount, and side-entry designs. Engineers should consider:

• Automated assembly compatibility

• Card insertion direction & clearance

• Stress distribution on solder joints

• Controlled impedance routing for high-speed signals

Proper footprint design and grounding significantly improve connector longevity and signal integrity.

4. Reference Case: Rugged SD Connectors for Automotive & Industrial Systems

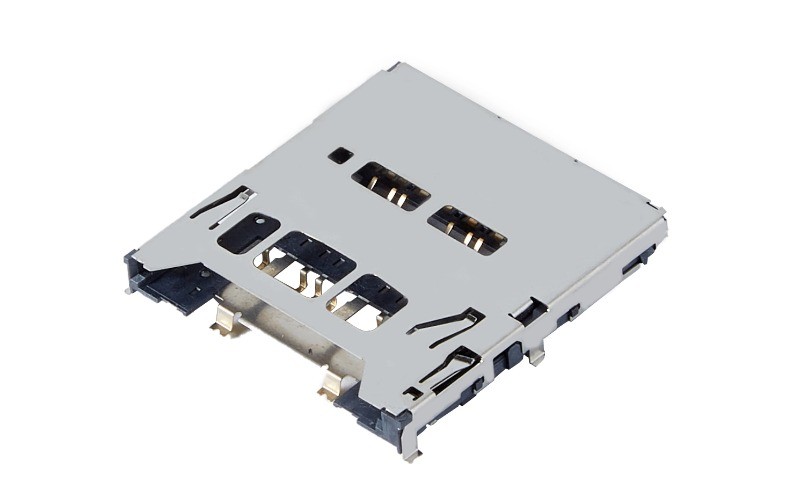

Rugged SD connector solutions such as JAE SG50 Series demonstrate how industrial-grade connectors address harsh environments with:

• Push-push mechanism

• Dual-contact structure

• Up to +105°C operating temperature

• Proven vibration resistance for automotive electronics

5. Why Choose MoarConn SD Memory Connectors

MoarConn specializes in the design and manufacturing of high-reliability SD Memory connectorsfor industrial and automotive applications. With over 20 years of connector expertise, we provide:

• Industrial-grade durability & extended lifecycle

• Gold-plated, high-retention contact systems

• Custom solutions for mounting, pin configuration, and detection switches

• Full support from design consultation to mass production

Learn more at www.moarconn.com

6. Conclusion

Selecting the right SD Memory connector is a critical step in building reliable industrial and automotive systems. By focusing on durability, electrical performance, environmental resistance, and proper PCB integration — and by partnering with experienced manufacturers like MoarConn — engineers can ensure long-term system stability and performance.